How traditional mechanical, room sized CNC machines transition to desktop machines (such as Bantam tools desktop CNC milling machine and Bantam tools desktop PCB milling machine) is due to the development of personal computers, microcontrollers and other electronic equipment components. Without these developments, powerful and compact CNC machine tools would not be possible today.

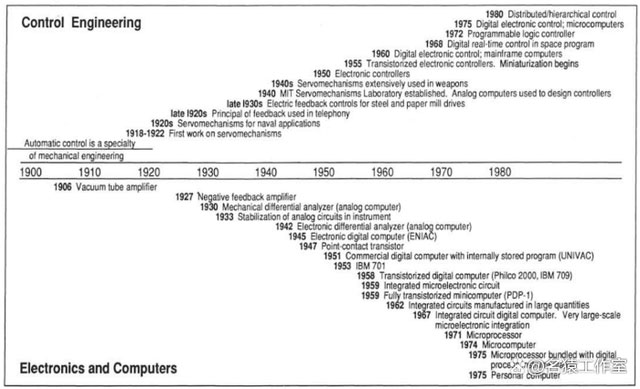

By 1980, the evolution of control engineering and the timetable for the development of electronic and computer support.

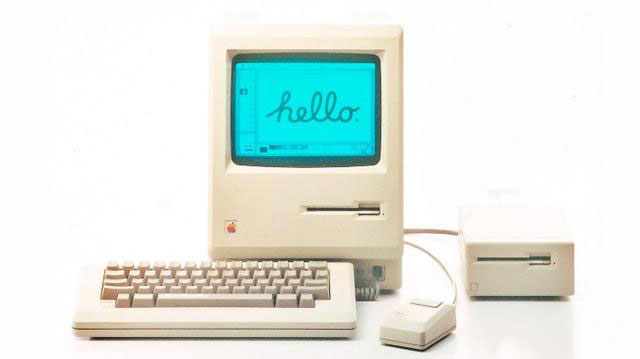

Dawn of personal computer

In 1977, three “microcomputers” were released simultaneously – Apple II, pet 2001 and TRS-80 – in January 1980, byte magazine announced that “the era of ready-made personal computers has arrived”. The development of personal computers has been rapidly upgraded since then, when the competition between apple and IBM ebbed and flowed.

By 1984, Apple released the classic Macintosh, the first mass-produced mouse driven personal computer with a graphical user interface (GUI). Macintosh comes with macpaint and macwrite (which popularize WYSIWYG WYSIWYG applications). The following year, through cooperation with adobe, a new graphics program was launched, laying the foundation for computer aided design (CAD) and computer aided manufacturing (CAM).

Development of CAD and cam programs

The intermediary between computer and CNC machine tool is two basic programs: CAD and cam. Before we delve into the brief history of both, here is an overview.

CAD programs support the digital creation, modification, and sharing of 2D or 3D objects. The cam program allows you to select tools, materials, and other conditions for cutting operations. As an engineer, even if you have completed all the CAD work and know the appearance of the parts you want, the milling machine does not know the size or shape of the milling cutter you want to use, or the details of your material size or type.

The cam program uses the model created by the Engineer in CAD to calculate the movement of the tool in the material. These motion calculations, called tool paths, are automatically generated by the cam program to achieve maximum efficiency. Some modern cam programs can also simulate on the screen how the machine uses the tool of your choice to cut materials. Instead of cutting tests on actual machine tools again and again, it can save tool wear, processing time and material consumption.

The origin of modern CAD can be traced back to 1957. The program named Pronto developed by computer scientist Patrick J. Hanratty is recognized as the father of cad/cam. In 1971, he also developed the widely used program Adam, which is an interactive graphic design, drawing and manufacturing system written in FORTRAN, aiming at cross platform omnipotence. “Industry analysts estimate that 70% of all 3-D Mechanical cad/cam systems available today can be traced back to Hanratty’s original code,” said the University of California Irvine, where he conducted the research at that time”.

Around 1967, Patrick J. Hanratty devoted himself to the computer-aided design of integrated circuit (CADIC) computers.

In 1960, the pioneering program Sketchpad of Ivan Sutherland was developed between the two programs of Hanratty, which was the first program to use a full graphical user interface.

It is worth noting that AutoCAD, launched by Autodesk in 1982, is the first 2D CAD program specifically for personal computers rather than mainframe computers. By 1994, AutoCAD R13 made the program compatible with 3D design. In 1995, SolidWorks was released with the clear purpose of making CAD design easier for a wider audience, and then Autodesk Inventor was launched in 1999, which became more intuitive.

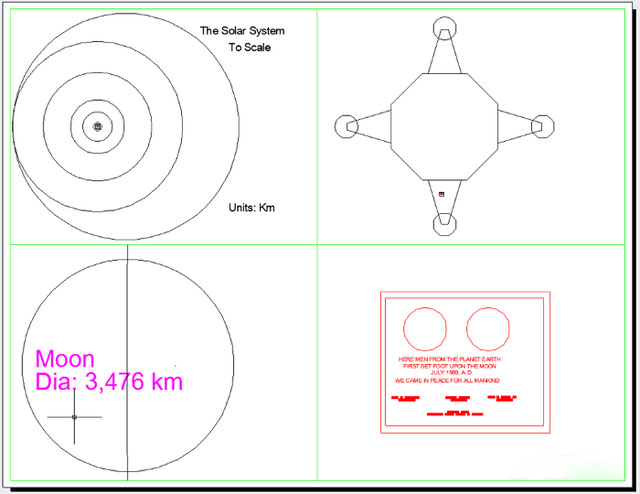

In the mid-1980s, a popular scalable graphic AutoCAD demo showed our solar system in 1:1 kilometers. You can even zoom in on the moon and read the plaque on the Apollo lunar lander.

It is impossible to talk about the development of CNC machines without paying tribute to the software creators who are committed to reducing the entry threshold of digital design and making it applicable to all skill levels. At present, Autodesk fusion 360 is at the forefront. (compared with similar software such as Mastercam, UGNX and PowerMILL, this powerful cad/cam software has not been opened in China.) it is “the first 3D CAD, cam and CAE tool of its kind, which can connect your entire product development process to a cloud based platform suitable for PC, MAC and mobile devices.” This powerful software product is free for students, educators, qualified start-ups and amateurs.

Early compact CNC machine tools

As one of the pioneers and ancestors of compact CNC machine tools, Ted hall, the founder of shopbot tools, was a professor of Neuroscience at Duke University. In his spare time, he likes to make plywood boats. He looked for a tool that was easy to cut plywood, but even the price of using CNC milling machines at that time exceeded $50000. In 1994, he showed a group of people the compact mill he designed in his workshop, thus starting the company’s journey.

From factory to desktop: MTM snap

In 2001, the Massachusetts Institute of Technology (MIT) established a new bit and atom center, which is the sister Laboratory of the MIT Media Laboratory, and is headed by the visionary Professor Neil Gershenfeld. Gershenfeld is considered to be one of the founders of the Fab Lab (Manufacturing Laboratory) concept. With the support of the US $13.75 million information technology research award from the National Science Foundation, the bit and atom Center (CBA) began to seek help to create a small studio network to provide the public with personal digital manufacturing tools.

Prior to that, in 1998, Gershenfeld opened a course called “how to make (almost) anything” at the Massachusetts Institute of technology to introduce technical students to expensive industrial manufacturing machines, but his course attracted students from different backgrounds, including art, design and architecture. This has become the foundation of the personal digital manufacturing revolution.

One of the projects born of CBA is machines that make (MTM), which focuses on the development of rapid prototypes that can be used in wafer factory laboratories. One of the machines born in this project is the MTM snap desktop CNC milling machine created by students Jonathan ward, Nadya peek and David Mellis in 2011. Using heavy-duty snap HDPE plastic (cut from the kitchen chopping board) on a large shopbot CNC milling machine, this 3-axis milling machine runs on a low-cost Arduino microcontroller, and can accurately mill everything from PCB to foam and wood. At the same time, it is installed on the desktop, portable and affordable.

At that time, although some CNC milling machine manufacturers such as shopbot and epilog were trying to release smaller and cheaper desktop versions of milling machines, they were still quite expensive.

MTM snap looks like a toy, but it has completely changed desktop milling.

In the spirit of a true Fab Lab, the MTM snap team even shared their bill of materials so that you can make it yourself.

Shortly after the creation of MTM snap, team member Jonathan ward worked with engineers Mike Estee and Forrest green and materials scientist Danielle applestone to carry out a DARPA funded project called mentor (manufacturing experiment and promotion) to “serve the 21st century.”

The team worked at otherlab in San Francisco, recombined and re examined the design of MTM snap machine tool, with the goal of manufacturing a desktop CNC milling machine with reasonable price, accuracy and ease of use. They named it othermill, which is the predecessor of Bantam tools desktop PCB milling machine.

Evolution of three generations of othermill

In May, 2013, the team of other machine Co. successfully launched a crowdfunding activity. A month later, in June, shopbot tools launched a campaign (also successful) for a portable CNC machine called handibot, which is designed to be used directly on the work website. The main quality of these two machines is that the accompanying software – otherplan and fabmo – are designed to become intuitive and easy-to-use WYSIWYG programs, respectively, so that a wide audience can use CNC processing. Obviously, as the support of these two projects proves, the community is ready for this type of innovation.

Handibot’s iconic bright yellow handle announces its portability.

Continuous trend from factory to desktop

Since the first machine was put into commercial use in 2013, the desktop digital manufacturing movement has been upgraded. CNC milling machines now include all types of CNC machines from factories to desktops, from wire bending machines to knitting machines, vacuum forming machines, water jet cutting machines, laser cutting machines, etc.

The types of CNC machine tools transferred from factory workshops to desktops are growing steadily.

The development goal of the Fab laboratory, originally born at MIT, is to popularize powerful but expensive digital manufacturing machines, arm smart minds with tools, and bring their ideas into the physical world. Only experienced people can obtain past professionals with these tools. Now, the desktop manufacturing revolution is further advancing this approach, from Fab laboratories to personal workshops, by significantly reducing costs while maintaining professional accuracy.

As this trajectory continues, there are exciting new developments in integrating artificial intelligence (AI) into desktop manufacturing and digital design. How these developments continue to affect manufacturing and innovation remains to be seen, but we have come a long way from the era of room sized computers and powerful manufacturing tools completely bound to large institutions and companies. Power is now in our hands.

Post time: Jul-19-2022