In essence, machine tool is a tool for machine to guide the tool path – not by direct, manual guidance, such as manual tools and almost all human tools, until people invented machine tool.

Numerical control (NC) refers to the use of programmable logic (data in the form of letters, numbers, symbols, words or combinations) to automatically control machining tools. Before it appeared, processing tools were always controlled by manual operators.

Computer numerical control (CNC) refers to sending accurately encoded instructions to the microprocessor in the machining tool control system, so as to improve the accuracy and consistency. CNC that people talk about today almost all refers to milling machines connected to computers. Technically speaking, it can be used to describe any machine controlled by a computer.

In the past century, many inventions have laid the foundation for the development of CNC machine tools. Here, we look at four basic elements of the development of numerical control technology: early machine tools, punch cards, servo mechanisms and automatic programming tools (APT) programming language.

Early machine tools

During the second industrial revolution in Britain, James Watt was praised for creating the steam engine that powered the industrial revolution, but he encountered difficulties in manufacturing the accuracy of steam engine cylinders until 1775, John Johnwilkinson created what is known as the world’s first machine tool for boring steam engine cylinders and was solved. This boring machine is also designed by Wilkinson based on his original cannon;

Punch card

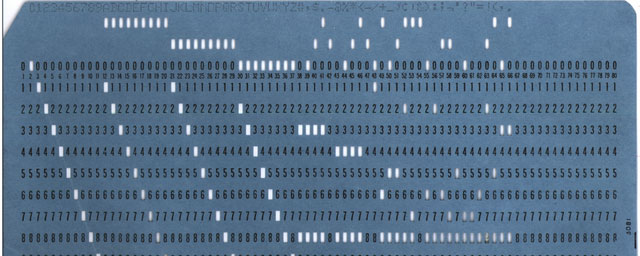

In 1725, Basile bouchon, a French textile worker, invented a method of controlling looms by using encoded data on paper tapes through a series of holes. Although it is groundbreaking, the disadvantage of this method is also obvious, that is, it still needs operators. In 1805, Joseph Marie jacquard adopted this concept, but it was strengthened and simplified by using stronger punched cards arranged in sequence, thereby automating the process. These punched cards are widely considered to be the basis of modern computing and mark the end of the home handicraft industry in weaving.

Interestingly, jacquard looms were resisted by silk weavers at that time, who worried that this automation would deprive them of their jobs and livelihoods. They repeatedly burned the looms put into production; However, their resistance proved futile, because the industry recognized the advantages of automated looms. By 1812, 11000 jacquard looms were in use in France.

Punched cards developed in the late 1800s and found many uses, from telegraph to automatic piano. Although mechanical control was decided by early cards, American inventor Herman Hollerith created an electromechanical punch card tabulator, which changed the rules of the game. His system was patented in 1889, when he was working for the U.S. Census Bureau.

Herman Hollerith founded the tabulator company in 1896 and merged with four other companies to establish IBM in 1924. In the second half of the 20th century, punched cards were first used for data input and storage of computers and numerical control machines. The original format has five rows of holes, while the subsequent versions have six, seven, eight or more rows.

Servo mechanism

Servo mechanism is an automatic device, which uses error inductive feedback to correct the performance of the machine or mechanism. In some cases, servo allows high-power devices to be controlled by devices with much lower power. The servo mechanism is composed of a controlled device, another device that gives commands, an error detection instrument, an error signal amplifier and a device (servo motor) that corrects errors. Servo systems are usually used to control variables such as position and speed, and the most common are electric, pneumatic or hydraulic.

The first electric servo mechanism was founded by H. calendar in Britain in 1896. By 1940, MIT created a special servo mechanism laboratory, which originated from the increasing attention of the Department of electrical engineering to this topic. In CNC machining, servo system is very important to achieve the tolerance accuracy required by automatic machining process.

Automatic programming tool (APT)

Automatic programming tool (APT) was born in the servo mechanism Laboratory of Massachusetts Institute of technology in 1956. It is a creative achievement of the computer application group. It is an easy-to-use high-level programming language, which is specially used to generate instructions for CNC machine tools. The original version was earlier than FORTRAN, but later versions were rewritten with Fortran.

Apt is a language created to work with MIT’s first NC machine, which is the world’s first NC machine. Then it continued to become the standard of computer-controlled machine tool programming, and was widely used in the 1970s. Later, the development of apt was sponsored by the air force and was eventually opened to the civilian sector.

Douglas T. Ross, the head of the computer application group, is known as the father of apt. He later coined the term “computer aided design” (CAD).

The birth of numerical control

Before the emergence of CNC machine tools, the first is the development of CNC machine tools and the first CNC machine tools. Although there are some differences in the different descriptions of historical details, the first CNC machine tool is not only a response to the specific manufacturing challenges faced by the military, but also a natural development of the punch card system.

“Digital control marks the beginning of the second industrial revolution and the arrival of the scientific era in which the control of machines and industrial processes will change from imprecise drafts to accurate ones.” – Association of manufacturing engineers.

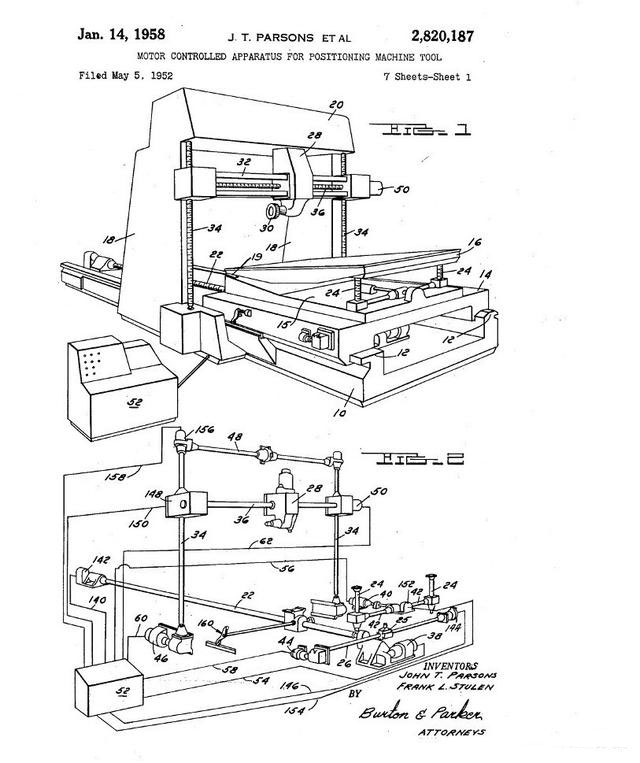

American inventor John T. Parsons (1913 – 2007) is widely regarded as the father of numerical control. He conceived and implemented numerical control technology with the help of aircraft engineer Frank L. stulen. As the son of a manufacturer in Michigan, Parsons began working as an assembler in his father’s factory at the age of 14. Later, he owned and operated a number of manufacturing plants under the family business Parsons manufacturing company.

Parsons has the first NC patent and was selected into the National Inventors Hall of fame for its pioneering work in the field of numerical control. Parsons has a total of 15 patents, and another 35 are granted to his enterprise. The society of manufacturing engineers interviewed Parsons in 2001 to let everyone know his story from his perspective.

Early NC schedule

1942:john T. Parsons was subcontracted by Sikorsky Aircraft to manufacture helicopter rotor blades.

1944: due to the design defect of the wing beam, one of the first 18 blades they manufactured failed, resulting in the death of the pilot. Parsons’ idea is to punch the rotor blade with metal to make it stronger and replace glue and screws to fasten the assembly.

1946: people wanted to create a manufacturing tool to accurately produce blades, which was a huge and complex challenge for the conditions at that time. Therefore, Parsons hired aircraft engineer Frank stulen and formed an engineering team with three other people. Stulen thought of using IBM punch cards to determine the stress level on the blade, and they rented seven IBM machines for the project.

In 1948, the goal of easily changing the motion sequence of automatic machine tools was achieved in two main ways – compared with just setting a fixed motion sequence – and is being carried out in two main ways: tracer control and digital control. As we can see, the first one needs to make a physical model of the object (or at least a complete drawing, such as Cincinnati cable tracer hydropower phone). The second is not to complete the image of the object or part, but only to abstract it: mathematical models and machine instructions.

1949: the US air force needs the help of ultra precision wing structure. Parsons sold his CNC machine and won a contract worth $200000 to make it a reality.

1949: Parsons and stulen have been working with Snyder machine & tool Corp. to develop machines and realized that they needed servo motors to make machines work accurately. Parsons subcontracted the servo system of “card-a-matic milling machine” to the servo mechanism Laboratory of Massachusetts Institute of technology.

1952 (may): Parsons applied for a patent for “motor control device for positioning machine tools”. He granted the patent in 1958.

1952 (August): in response, MIT applied for a patent for “numerical control servo system”.

After World War II, the U.S. Air Force signed several contracts with Parsons to further develop the NC machining innovation made by its founder John Parsons. Parsons was interested in the experiments being carried out in the servo mechanism Laboratory of MIT and proposed that MIT become a project subcontractor in 1949 to provide expertise in automatic control. In the next 10 years, MIT gained control of the whole project, because the vision of “three-axis continuous path control” of servo laboratory replaced Parsons’ original concept of “cut in cutting positioning”. Problems always shape technology, but this special story recorded by historian David noble has become an important milestone in the history of technology.

1952: MIT demonstrated their 7-rail perforated belt system, which is complex and expensive (250 vacuum tubes, 175 relays, in five refrigerator sized cabinets).

MIT’s original CNC milling machine in 1952 was hydro Tel, a modified 3-axis Cincinnati milling machine company.

There are seven articles about “self regulating machine, which represents a scientific and technological revolution that will effectively shape the future of mankind” in the journal “automatic control” of Scientific American in September, 1952.

1955: Concord controls (composed of members of MIT’s original team) created numericard, which replaced the perforated tape on MIT NC machines with the tape reader being developed by GE.

Tape storage

1958: Parsons obtained U.S. patent 2820187 and sold the exclusive license to Bendix. IBM, Fujitsu and general electric all obtained sub licenses after they began to develop their own machines.

1958: MIT published a report on NC economics, which concluded that the current NC machine did not really save time, but transferred the labor force from the factory workshop to the people who made perforated belts.

Post time: Jul-19-2022